Type Three Tuning Page -- Full Flow Oil Filtering System

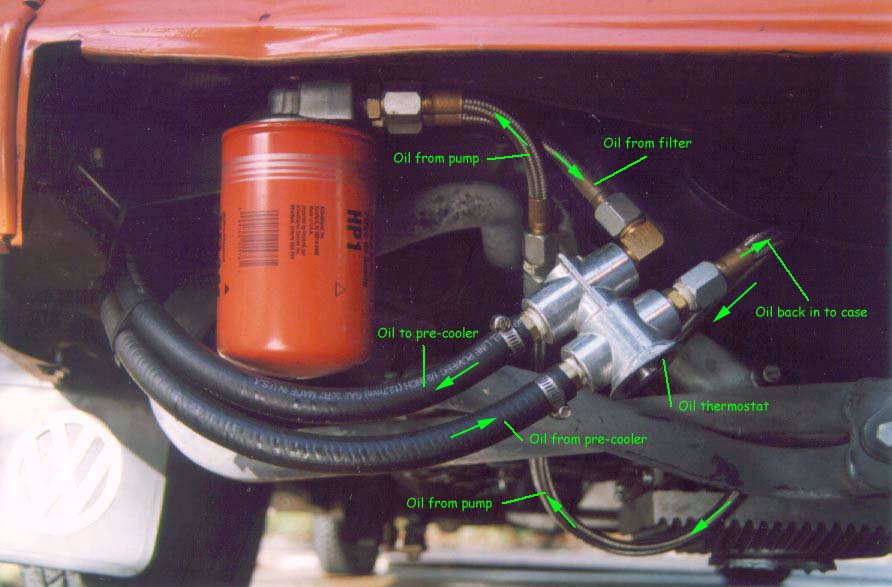

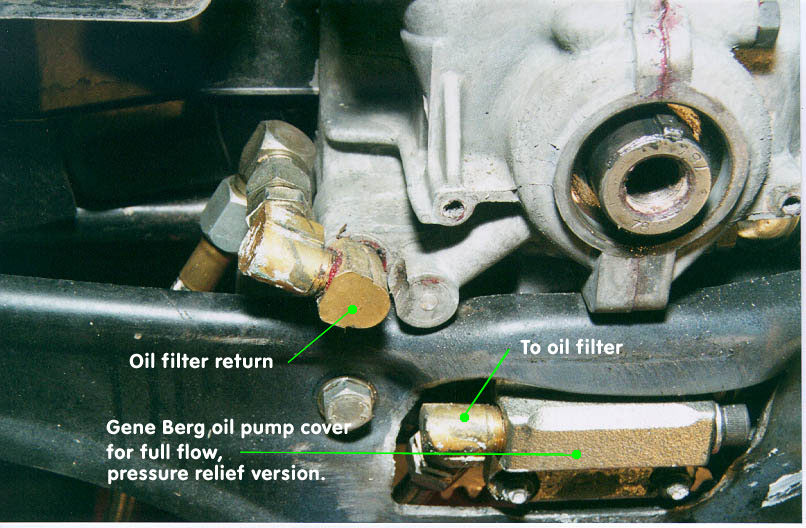

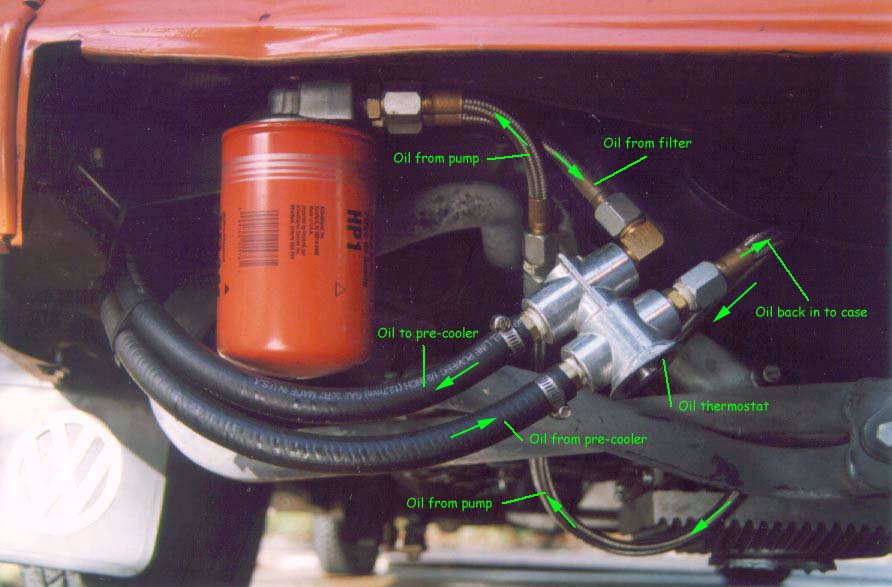

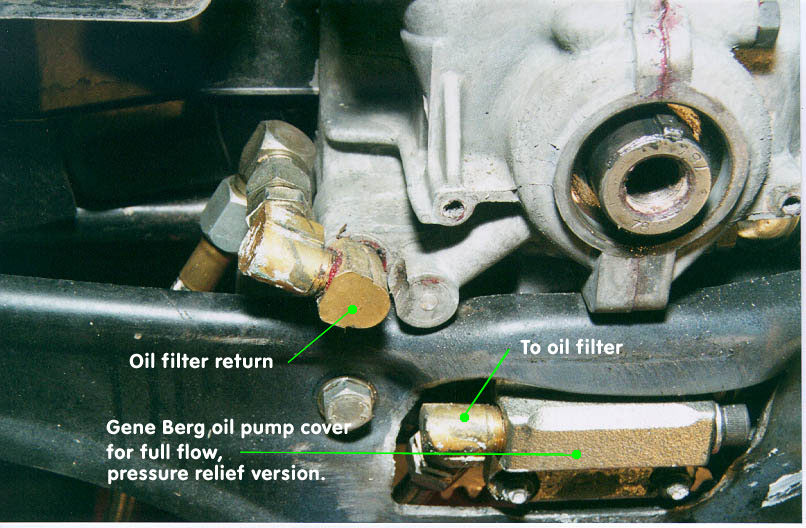

Full flow oil system

Click on image for larger view

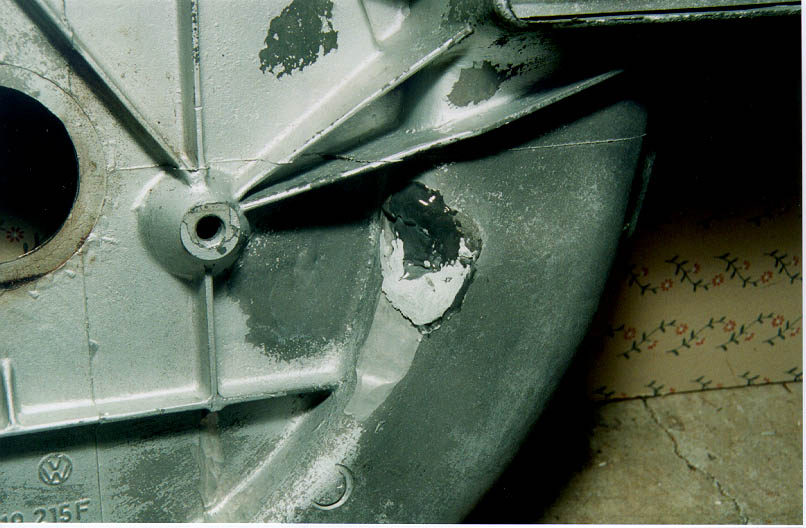

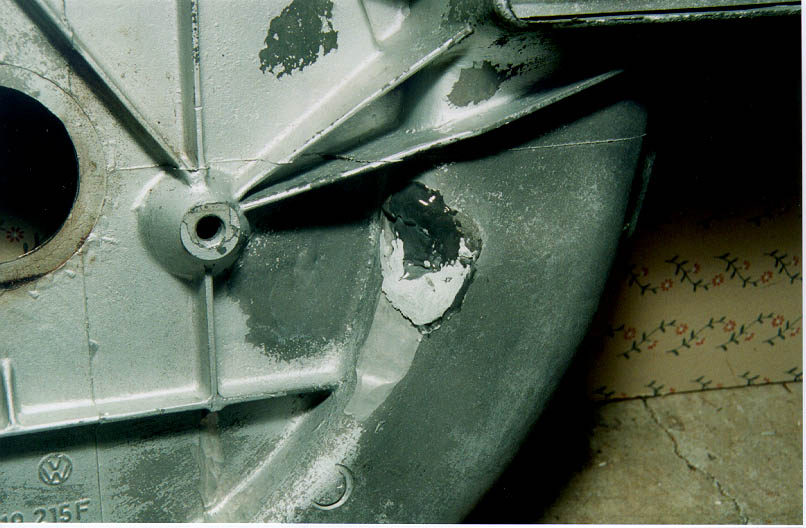

Front of fan housing. JB Weld (epoxy) covering hole to clear input oil fitting.

Front of fan housing. JB Weld (epoxy) covering hole to clear input oil fitting.

Oil pre-cooler installation.

Used in conjunction with an oil thermostat AND a full-flow oil filtering system.

48-plate Mesa oil cooler from Kymco Motorsport, Inc. Tube-and-fin style coolers are not effective enough in a confined space such as this.

Bracket is 1/4 inch solid steel, bent to fit using a simple bench vise. Fan is thermostatically controlled to turn on at pre-sets of 180-degrees F and off at 160-degrees F -- this is user-adjustable.

Fan is held on with nylon wire ties and brackets through available holes in cooler and fan. Spacers on bracket are just fuel line hose. Bracket is held to vehicle by cotter pins mounted on the upper cargo floor in the cabin. Straight leg of cotter pin goes through hole drilled in bracket.

- Bracket and cooler/fan assembly side/bottom view.

- Bracket and cooler/fan assembly side/top view.

- Bracket and cooler/fan assembly side view (notice uneven bracket lengths, longer ones go in front).

- Rubber grommets in upper cargo floor where brackets are clipped in.

- Rubber grommets in lower cargo floor where brackets enter.

- Brackets clipped in with curved cotter-style pins.

- Assembly in on right side of car. In/out ports facing left side of car.

- How it looks installed, starter and heater tubing removed (white air-shock is custom).

- Shows gap between cooler and starter and heating tubing -- no interference!

- Another picture showing the clearance.

- Positioning picture to show approximate distances.

- Ruler giving approximate location. Positioning and precise drilling was difficult, thus holes are uneven.

- Positioning picture. Notice waste heat dumps more on heating tubing and barely on starter and none on tranny.

Why do I think this is a safe set up? Here goes...

I spent a LOT of time thinking about my system -- hey, with Jim A. and Keith P. playing devil's advocates I gotta play engineer and be on my toes :) Plus, with the amount of money I've put into my engines I can't afford to mess things up! Pressure drops, thermostats, oil temps (overheating, underheating, and operating temps), and cooler location (in the spare tire well, above the tranny, under the axle, ???) all played a part in the decision process.

Oil first enters the filter then goes to the oil thermostat. No matter where it goes, it'll be clean. Now, if it's below 180-F it flows back into the case before the oil pressure relief valve. If it's greater than 180-F it is diverted to the pre-cooler, the 48-plate Mesa oil cooler. This is a radiator-type cooler and not one of the inferior tube-and-fin ones. The oil then enters back into the case (again, before the oil pressure relief valve). Now, should the oil be too hot it then goes into the stock oil cooler for further cooling; just right or too cool then past, or partially in, the stock cooler (according to the oil pressure relief valve). If the oil is too hot when it enters the pre-cooler a thermostatic fan clicks on and blows through the radiator to further help cool it down. It will switch off if the temp should drop (user adjustable on/off temp).

Note: Some oil will still pass through the pre-cooler when it's cold. This is a function of the oil thermostat as it does not completely close. According to the thermo manufacturer this keeps foaming, surging and stagnation from occurring to the oil in the by-pass loop.

My system setup allows filtered oil to enter the engine and be regulated by the engine according to the proper operating temp set by the engineers. The stock cooling system is never compromised, only assisted, which is why I call it a pre-cooler and not a secondary cooler which would imply an "always on" oil cooler, either in parallel or serial, and generally installed after the pressure relief valve. The oil thermostat has only one INPUT (the oil from the filter) and only one OUTPUT (tapped into the case before the oil pressure relief valve). Only when the oil is in the thermostat does it either get routed [when cool] to the OUTPUT and a tiny bit to the bypass, or [when hot] directly through the bypass loop i.e. oil pre-cooler. I also don't like the idea of hot air caressing my 5-speed -- the tranny gets hot enough, why make it worse? Plus, when the fan is on I can feel the heat being blown down and get an small idea of how hot the oil is.

By removing the stock oil cooler and putting in a secondary one or rerouting it you run the chance of over/undercooling the oil, which isn't good, as well as undercooling the #3 cylinder head. Now, I haven't done the math on the #3 cooling but I think it would be a safe guess that the engineers worked out the necessary cooling differences involved.

My fan gets its power from the coil so when the car is ON the fan is on. This allows me to kill the engine then put power back to the coil, thus allow the fan to continue to cool the oil in the pre-cooler while the engine is off (yes, it does help).

Front of fan housing. JB Weld (epoxy) covering hole to clear input oil fitting.

Front of fan housing. JB Weld (epoxy) covering hole to clear input oil fitting.