Type Three Tuning Page -- Heating system

Please select the area of interest:

Stock

Get a gas heater installed and you'll have too much heat!

Seriously, though, with snug hose connections AND INSULATION around the hoses that go from the heat exchangers to the body, you will get good-n-toasty...at least around your feet. Those with a proper, tight system, and had the original upper heat exchangers noticed a lessening of the heating system when going to one that didn't include the upper heat exchangers. I drove thousands of miles with just my lower heat exchangers but I had tight hose connections and insulation around them and it kept me warm in freezing weather. Leaks from the rockers -- where there's a separate metal tube for the heat to go through -- can cause a loss of heat due to rust perforation and/or inadequate rocker replacement. Forget about a "booster fan" (which is just an over-priced bilge fan you can find at a boating store) as it won't produce any more heat and it's just a bandaide for a broken leg i.e. it won't fix a poorly operating heating system.

Here is a good alternative for the flexible pipe that connects the heat

exchanger to the cabin. This hose also has built-in clamps at each end so

there's no need for metal hose clamps. Remember to put insulation around it!

Click

on image for a larger picture.

Click

on image for a larger picture.

Custom

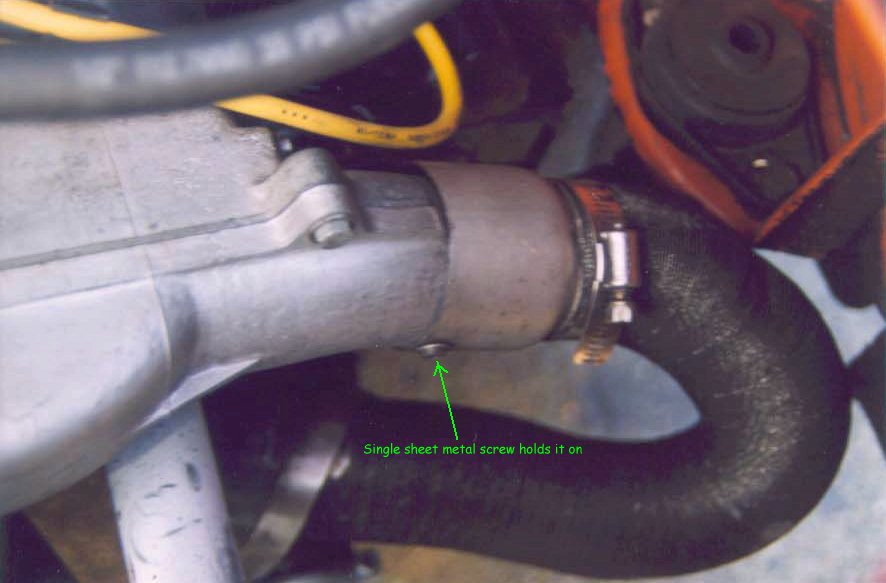

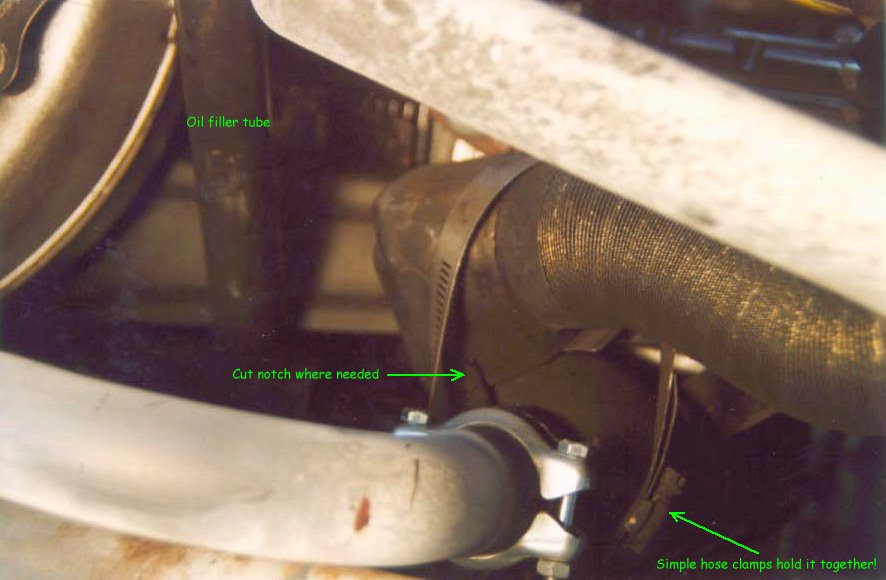

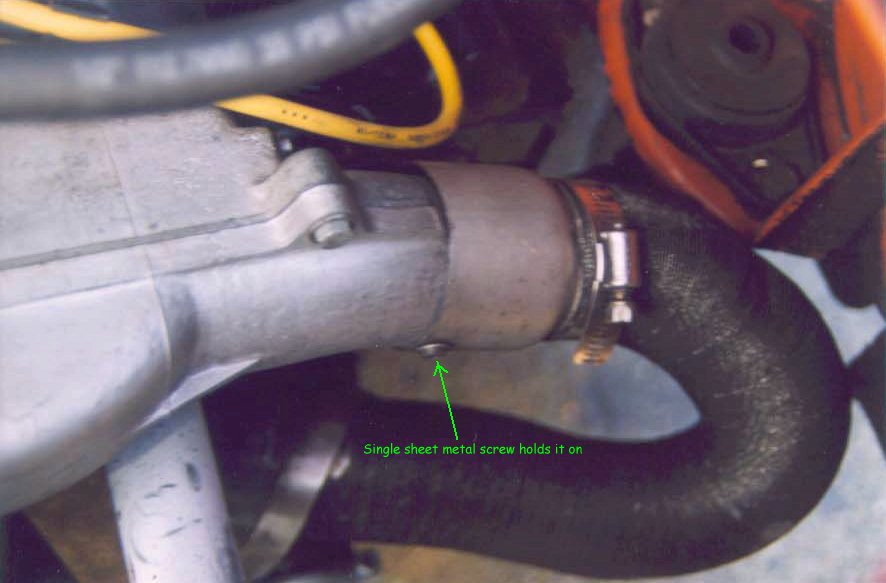

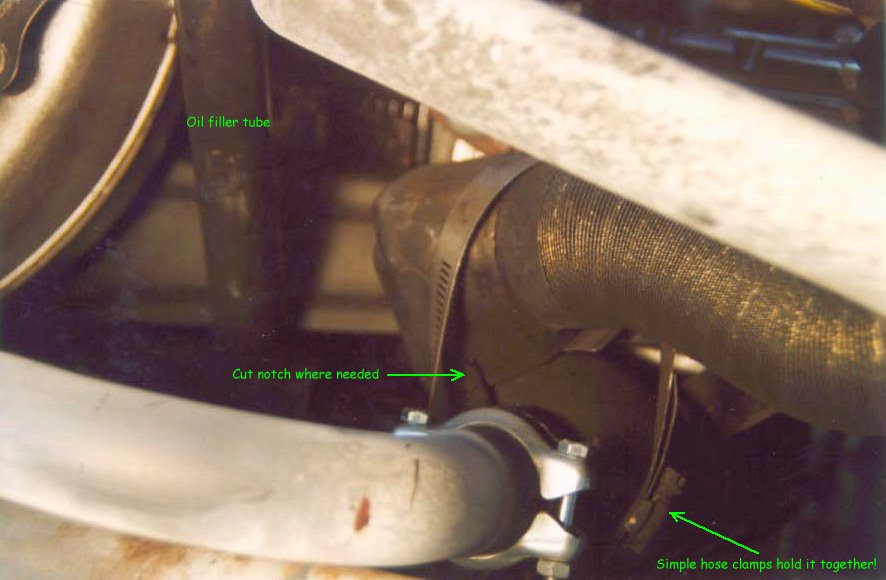

My custom, "bullet-proof" fresh air system for supplying my heaters. I had this

done because my higher-performance engine kept blowing apart the stock hosing,

causing that nausiating, expensive over-heating smell that our engines get when

they loose their cooling air. This is my original system and it's been in place

since '92-'93!

The hose is generic, fiberglass impregnated carburator heater hose found in any

auto parts store. The aluminum ends were made at a plain muffler shop. I backed

my Squareback in to the bay, showed the dude the hose, and told him I needed the

hose to fit over the ends and the ends to fit on to the car parts (fan housing

and heat exchanger). The top pieces were flared to fit while the bottom piece

had to be welded (he did it right in the shop as I stood there). I took the

pieces home and drilled the hole for the sheet metal retaining screw for the top

pieces and cut the notch in the lower pieces so they would fit lower on to the

heat exchanger. For an experienced muffler shop this stuff is super easy for

them and will be very cheap for you. Take the hose and car if you can and show

them these pictures to help them out.

Click

on image for a larger picture.

Click

on image for a larger picture.