Shortening the shifter shaft by Toby Erkson

This is a simple and quick modification that will shorten the length of the shifter. This will NOT shorten the actual throw like a short throw kit, it will only shorten the height of the shifter and the distance the shift knob travels. Remember, this is a permanent modification so only take off a little bit at a time and test!

The first thing to do is put the car in neutral. Next, unscrew the shift knob then pop off the shifter surround base from the center console. This is easily pryed off with the help of a flat bladed screwdriver and pulling up with your fingers.

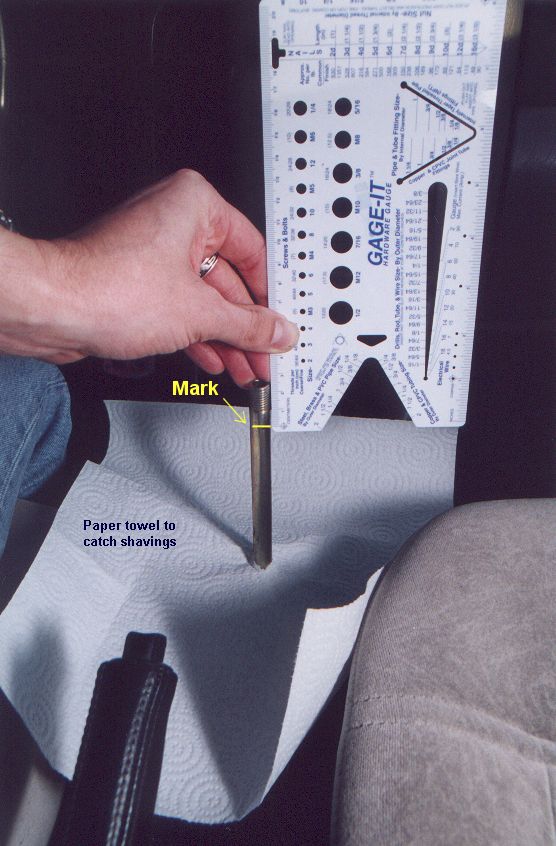

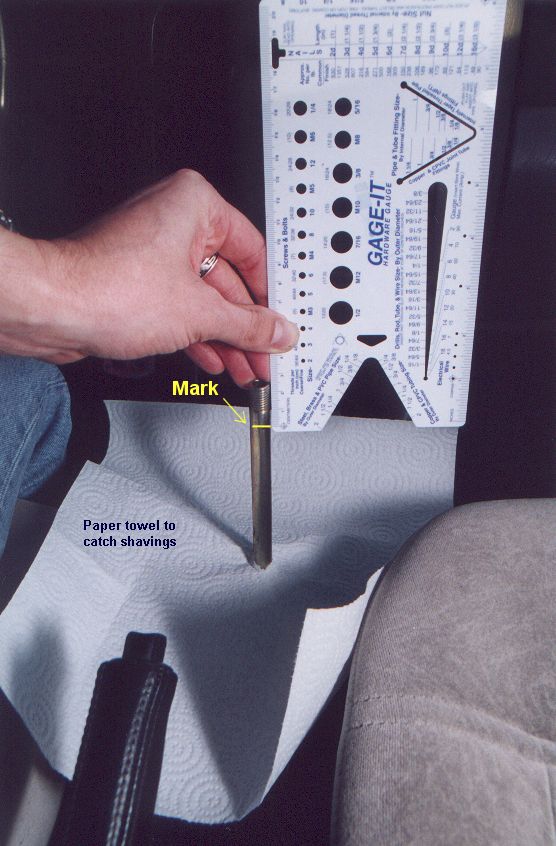

Now you want to put something down to protect the shifter base from becoming clogged with debris when you are cutting the new threads on the shifter. I used a paper towel but a piece of cloth would probably be a better idea.

To get a general idea of where to cut your threads to, take a ruler and draw a line with a permanent marker the distance you want to drop your shift know to, measuring from the bottom of the threads. As shown here, I've put a mark 1/2" below the threads:

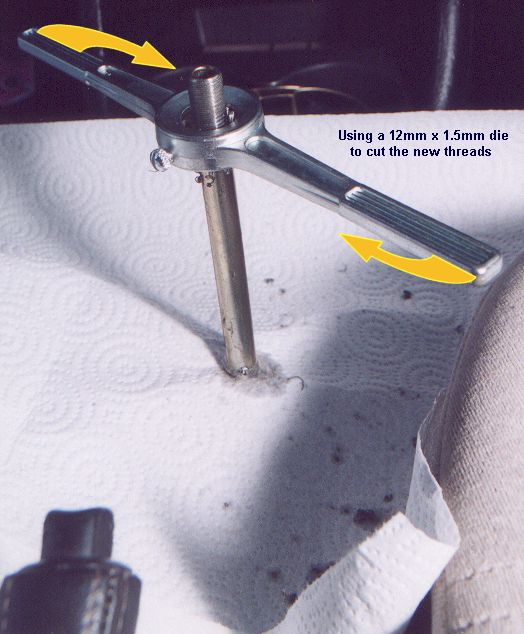

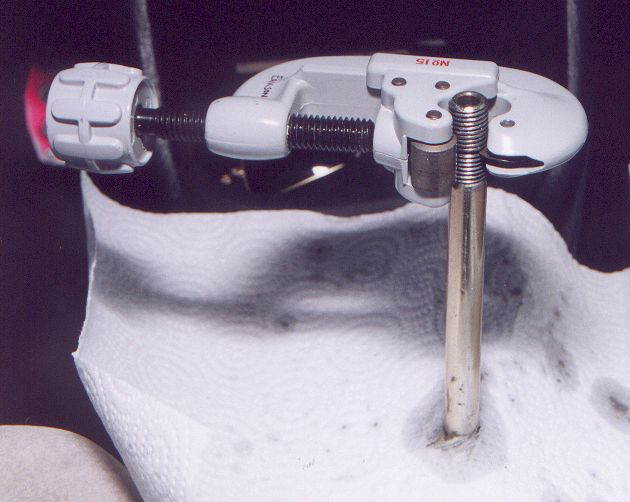

Because of all the idiots who rush this job and end up breaking some parts in their shifter, I add this piece of advice:

Clamp vice-grips to the shift shaft and hold them while cutting the new threads. This will keep the shift shaft from turning and breaking anything.

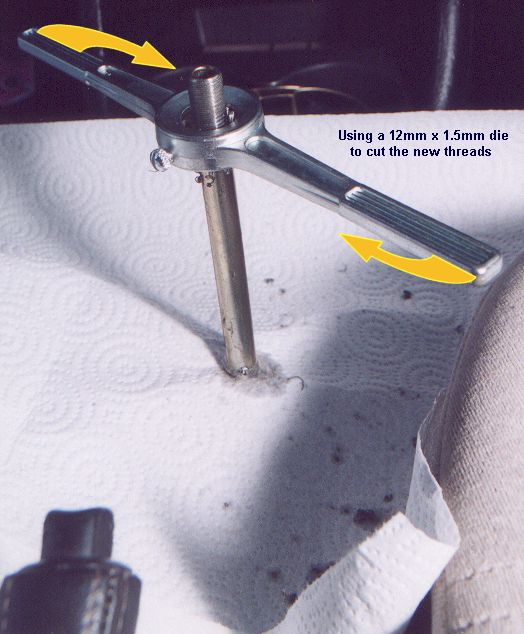

Apply cutting oil to the threads on the shifter and thread the die until it hits the bottom of the shifter threads. Begin cutting the new threads (follow the directions supplied with the tap & die kit or listen to someone who knows how to do this) down to the mark you made, remembering to back off every 1/4 - 1/2 turn to release the cut metal from the teeth.

Once you've reached your mark back off the die and wipe the metal shavings and oil from the threads on the shifter shaft. It'll be difficult to see so give it your best estimate; what I did was cut until the center of the die was about where the mark would be.

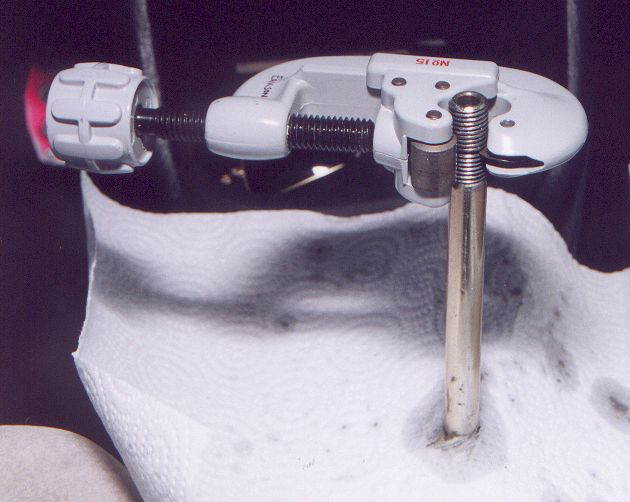

Now place the tubing cutter on the shaft the same distance you cut new threads to but measure from the top. Following my example, since I added 1/2" to the bottom of the threads I will cut 1/2" from the top of the shaft, as shown here:

Because the tubing cutter will follow the threads, you will need to rotate the tubing cutter 180° clock-wise, rotate it back to the 'home' position, rotate it counter clock-wise 180°, and return it to the 'home' position. Tighten the cutter and repeat until the shaft is snipped off. Once broke free, you will need to carefully re-thread the die onto the shaft threads since the roller on the tubing cutter will have dulled them some.

Now clean the threads of metal shavings and oil, then remove the filings catcher you put around the shifter assembly. Put the shift boot back on and screw the shift knob back on. Tighten carefully, there's no need to wrench down on it! Sit back and test the throw, your reach distance and determine if you can lower it some more (if you desire). When I cut mine down the 1/2" and tested it, it just didn't feel or look much different so I cut another 1/2", for a total one inch drop:

If you want to cut more off, just go through the whole procedure again now that you know it's pretty easy! When finished, vacuum the whole area, snap the shifter surround back on to the center console and screw the shift knob back on. Done!

Distance Old throw distance (w/Neuspeed short throw kit) After removing 1" from shifter shaft

1 -> 2 3.13" 2.50"

End of Document